Occupational Health and Safety

Occupational Health and Safety

Providing employees with a safe and healthy working environment is one of Chroma’s most fundamental responsibilities as a corporate citizen. The Company systematically promotes occupational safety and health management in accordance with the P-D-C-A cycle of the Occupational Safety and Health Management System across the headquarters (including Huaya Plant), the Hsinchu Branch, and the Kaohsiung Branch. In 2023, the Company successfully obtained ISO 45001:2018 certification for its Occupational Safety and Health Management System, and in 2024, an external audit confirmed the effective operation of the system, thereby maintaining the validity of the certification. The scope of the system covers: all employees, as well as nonemployees whose work is under the Company’s control (including contractors).

Each plant has established a dedicated Occupational Safety and Health (OSH) unit that reports directly to the highest-level supervisor of the site. Professional personnel are employed to plan, implement, supervise, and audit safety and health management tasks. In accordance with local regulations, each plant has also formed an Occupational Safety and Health Committee composed of both labor and management representatives. The committee convenes regularly to review, coordinate, and make recommendations on OSH matters, as well as to evaluate the performance indicators of each unit, thereby enhancing both workplace and environmental safety. The Safety & Health Center and production units have established standard operating procedures for workplace safety and health management. Regular education and training courses are held, along with simulations and drills for the environment, workplace, equipment, and chemical management, to ensure employee safety and health.

Hazard Identification, Risk Assessment

Chroma places great importance on ensuring the safety and health of its workers’ operating environments, upholding a spirit of proactive prevention. In 2024, the Company advanced digital transformation across all plant sites by implementing a systematic, comprehensive risk assessment to identify any regulatory conflicts among occupational safety, environmental protection, human resources, and facility management units. Simultaneously, a complete inventory of chemicals used across all plants was verified and established to identify substances hazardous to health. This enabled the Company to determine which items require workplace environment monitoring, are classified as hazardous chemicals, or fall under priority management substances, thereby allowing for corresponding response measures and regulatory reporting and control.

Personnel from the Safety & Health Center and the OSH promotion teams of each unit conduct a comprehensive hazard identification and risk assessment annually, in accordance with the “Regulations for Hazard Identification and Risk Assessment in Occupational Safety and Health Management.” This process covers all personnel working under the Company’s control (including the Company’s employees, contractors, and visitors). Based on the assessment results, a tiered management approach is adopted, with priority given to implementing control measures for risks deemed unacceptable. Employees may also proactively report identified workplace hazards to the Safety & Health Center via email or phone. Through joint efforts between labor and management, the Company continues to pursue the goal of zero accidents and zero harm.

Target and Scope of Hazard Identification and Risk Assessment

Personnel working under the Company’s control, including employees and contracted workers (such as cleaning staff, security

personnel, and catering service providers).

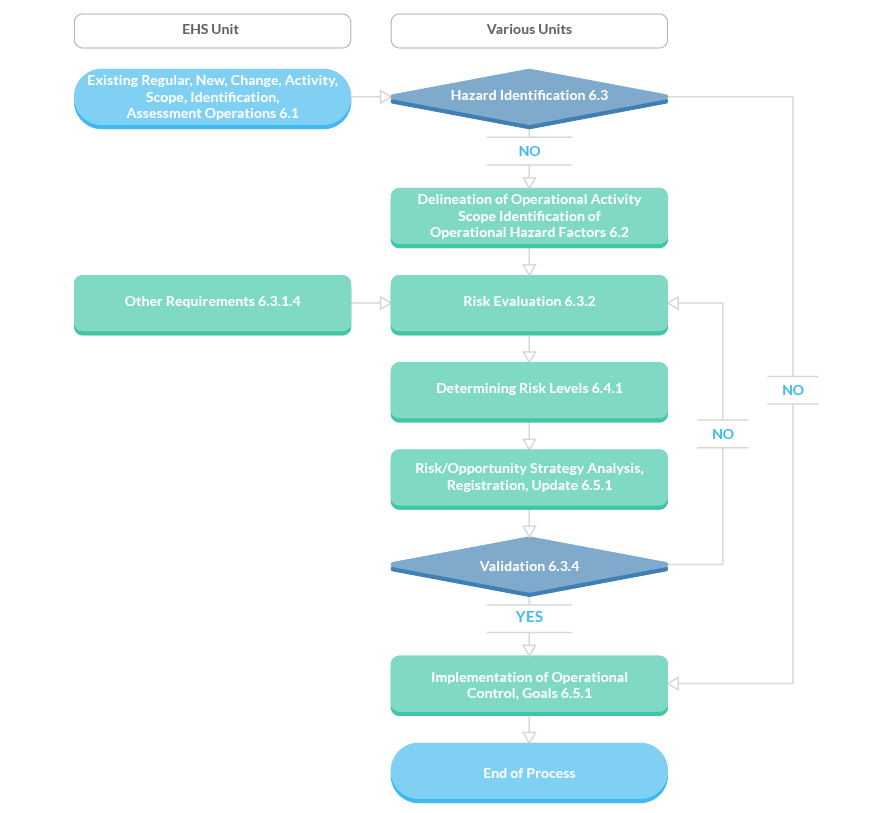

Hazard Identification and Risk Assessment Process

Potential hazards associated with the workplace environment, processes, activities, products, and services are identified, and corresponding risk levels are determined. Priority control measures are implemented for risks deemed unacceptable.

For contractors, hazard identification and risk assessment results are communicated during pre-work meetings or toolbox meetings, along with relevant control measures.

When new equipment is procured or process changes are introduced, change management procedures are carried out to ensure the safety and health of personnel and plant operations. Measures include conducting safety assessments prior to equipment purchase, adding protective features, or selecting lower-hazard chemicals to replace higher-risk substances.

Emergency Response Measures for Imminent Hazards

To effectively protect worker safety, Chroma emphasizes in its training programs that when there is an imminent danger in the workplace, the person in charge must immediately instruct workers to stop operations or allow them to stop on their own and retreat to a safe location. The Company ensures that no disciplinary action will be taken against employees for doing so.

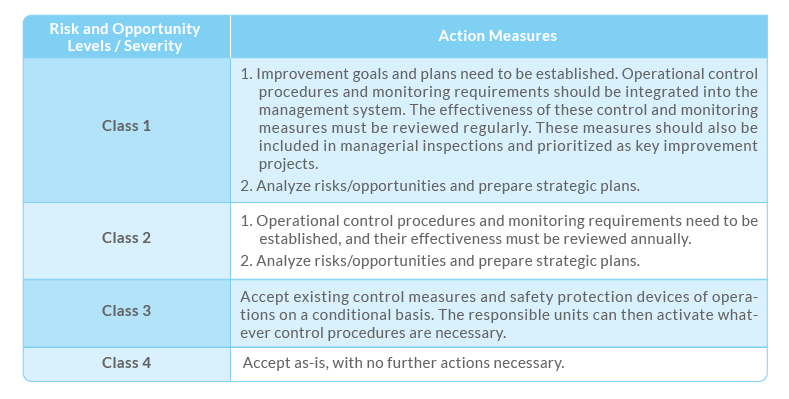

Operational Control / Action Measures (Tiered Risk Control Mechanism)

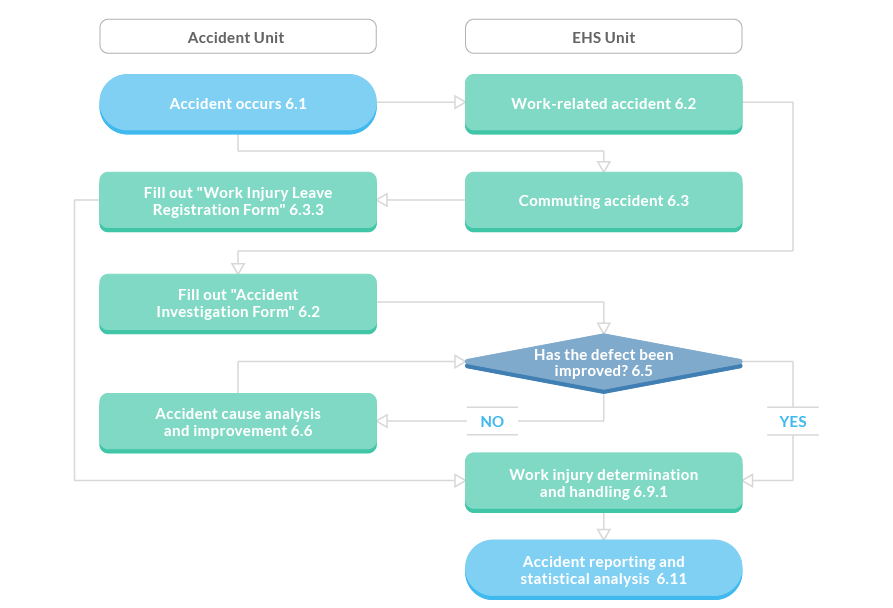

Accident Investigation

(1) Commuting Accidents: Accidents occurring on the necessary route between home and the workplace, including traffic

accidents and other unexpected incidents.

(2) Near miss: Incidents that cause no injury or casualty but result in a fright or alarm among personnel.

(3) Major accidents:

① Involves a fatality, three or more injured persons, or at least one person requiring hospitalization.

② Fire incident.

③ Accidents reported by mass media.

(4) Severe injury: Serious injuries resulting in the loss of function in certain organs (e.g., amputation, blindness, deafness).

(5) Minor injury: Occupational accidents causing injury without loss of workdays.

Incident Reporting and Data Analysis:

(1) The Environmental Protection, Safety and Health (ESH) unit shall compile and retain monthly statistics on the Frequency Rate (FR) and Severity Rate (SR) of disabling injuries.

(2) In accordance with the“ Occupational Safety and Health Act”, the ESH unit shall submit monthly occupational accident statistics to the labor inspection authority by the 10th of each month.

(3) In the event of a major accident, the ESH unit must report the incident to the labor inspection authority within 8 hours.

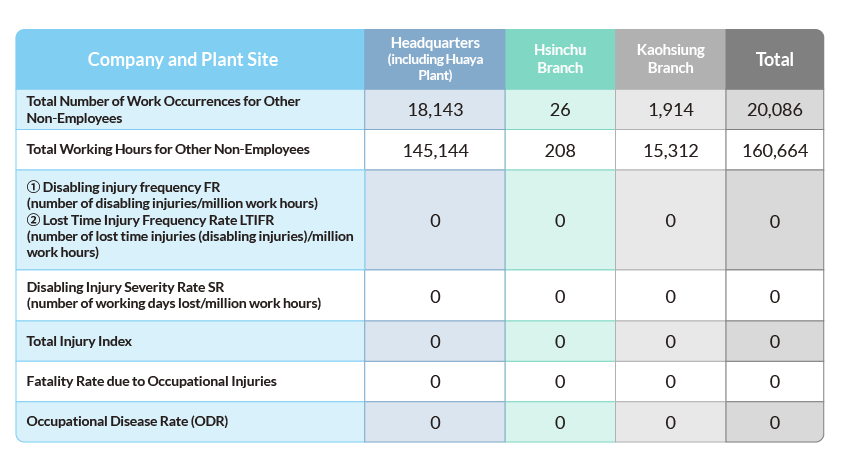

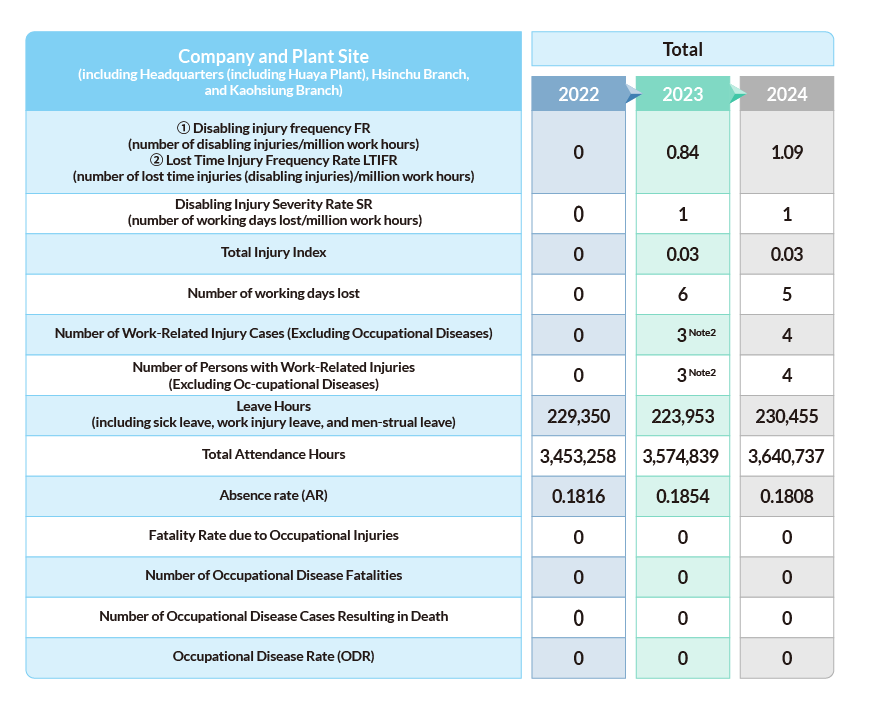

Statistics on occupational injuries and work-related accidents for employees from 2022 to 2024 across all plant sites, (including the headquarters (including Huaya Plant), Hsinchu Branch, and Kaohsiung Branch), are summarized in the table below

Note 1: Work-related injury statistics are based on incidents that occurred within the plant premises (excluding commuting accidents).

Note 2: Corrections have been made in the 2024 report after rechecking the calculation.

Calculation Method:

(1) Total working hours for other non-employees = Total number of work occurrences for other non-employees*8 hours.

(2) Disabling Frequency Rate (FR) = Number of disabling injuries *106/Total working hours.

(3) Disabling Severity Rate SR (SR) = Number of days lost due to a disabling injury*106/Total working hours.

(4) Lost Time injury frequency rate (LTIFR) = Number of lost time injuries / Total working hours × 1,000,000.

(5) Total injury index = √(FR*SR/1000).

(6) Absence rate (AR) = Number of days for sick or personal leave/Total number of working days x 100%.

(7) Occupational disease rate (ODR) = Total number of employees with occupational disease x 106/Total number of working hours.

Occupational Health and Safety Education

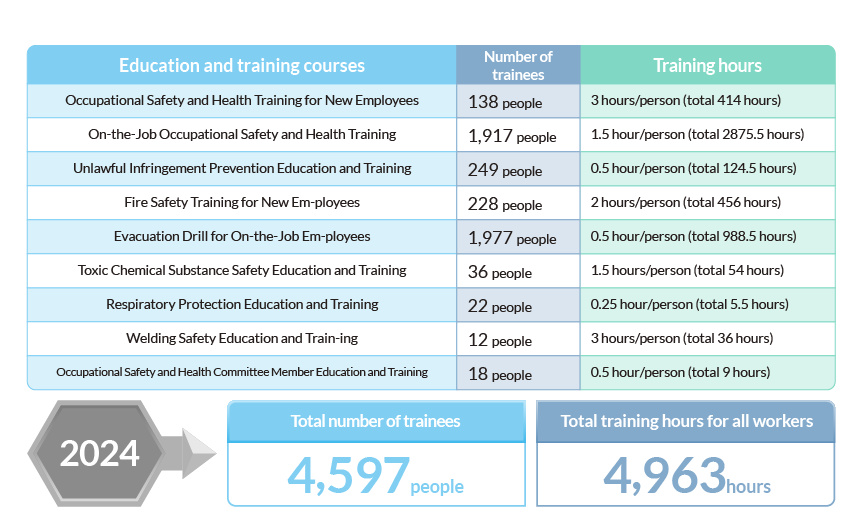

Chroma complies with the Occupational Safety and Health Education and Training Regulations and related requirements to ensure that every worker is familiar with relevant laws and the Company’s safety and health management mechanisms. New employees receive occupational safety and health training upon hiring, and post-training assessments are conducted to evaluate learning outcomes. For existing employees, the Company also holds safety and health training courses on an irregular basis to continuously instill fundamental safety concepts and encourage practical application in daily work. In addition, all regular occupational safety and health training sessions are conducted during working hours. Employees are not subject to any disadvantage, such as pay cuts, salary deductions, or leave deductions, for attending these trainings. In 2024, the total number of participants reached 4,597, with a cumulative total of 4,963 training hours completed by all workers. (as follows)

In addition, Chroma regards contractors as important work partners. While contractor management is complex, it is an indispensable part of operations. To ensure the safety of contractor personnel, two key aspects must be addressed: controlling personnel access to the plant and addressing the potential lack of safety awareness among contractors, who are not Company employees. In addition to daily toolbox safety briefings, first-time contractors receive hazard communication training conducted by the Safety & Health Center. Annual contractor training sessions are also held to ensure that all contractors understand the plant’s safety regulations.

For situations where multiple contractors are working simultaneously at the same time and location, Chroma not only establishes a coordination organization to facilitate communication and cooperation among the parties involved, but also informs contractor supervisors of recent violations and non-compliant cases identified during the quarter, serving as a warning and reminder to all. In addition to various inspection procedures, the Safety & Health Center and the project management units conduct an annual contractor evaluation at the end of each year. Contractors are categorized based on multiple evaluation criteria, and those who fail the assessment are recommended for replacement or discontinuation of cooperation. In 2024, there were zero contractor-related incidents at Chroma. However, we do not consider this a reason for complacency. We aim to achieve zero occupational injuries not only among our employees but also among all contractors working within our plant sites.

Prevention and mitigation of occupational health and safety impact directly linked to business relationships

To ensure the safety of workers and factories, each factory not only complies with government regulations and operating standards, but also conducts automatic and self-inspections; the Safety & Health Center staff also conducts routine safety inspections and irregular spot checks on contractors' operating safety. Under the operation of the ISO 45001:2018 Occupational Safety and Health Management System, the Safety & Health Center regularly conducts unscheduled inspections and collaborates with on-site physician services to propose improvements for certain operational activities. These efforts have yielded positive results.

Worker Participation, Consultation, and Communication

To reach a consensus on the environmental safety and health management system and the Company’s various management mechanisms, and to establish commitment and effective two-way communication channels between internal employees and external related parties regarding environmental safety and health management, the “Consultation and Communication Management Procedure” has been established. Workers shall be consulted whenever there are changes to safety and health conditions in any workplace. The consultation process shall be documented, such as: meeting notices or minutes, and relevant stakeholders shall be informed.

Employees are Chroma’s most valuable assets, and health and safety are their most important foundations. To ensure that employees work in a healthy and safe environment and to implement the Company’s occupational safety and health policies, Chroma has established the Occupational Safety and Health Committee. The committee comprises 18 members from the headquarters (including Huaya Plant), Hsinchu Branch, and Kaohsiung Branch. It is composed of occupational safety and health personnel, relevant department supervisors, and worker representatives. Among them, 8 are worker representatives, accounting for 44% of the committee, which exceeds the legally required minimum of one-third. The committee convenes once every three months and provides recommendations on the following items ▶

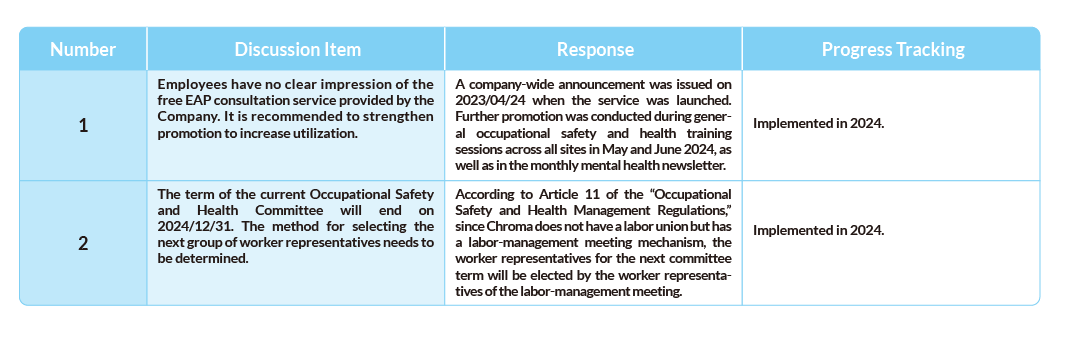

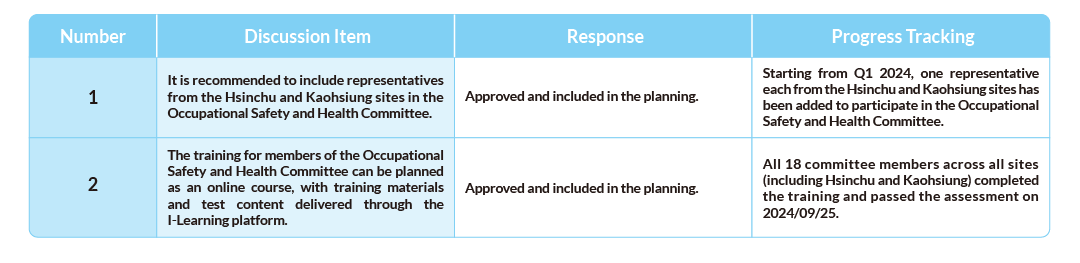

In 2023, the committee members proposed a total of 7 discussion items, of which 5 were completed within the same year, and the remaining 2 were fully implemented in 2024.

In 2024, the committee members proposed a total of 2 discussion items, both of which were completed within the same year.