Technology and Product

Chroma started with display testing, with a vision of developing precise, reliable, and unique testing instruments, and has gradually expanded into nine major product categories, including power electronics, passive components, and semiconductor and IC design testing. To meet customer demands for green products, the Company not only reduces the energy consumption of its equipment but also actively develops energy recovery equipment that recovers energy traditionally dissipated as heat back to the power grid, significantly reducing energy usage. In addition, Chroma continuously enhances the accuracy, testing speed, and reduction of size and weight of its testing equipment developed in-house to help users improve production efficiency. All of the above actions demonstrate Chroma’s efforts as a member of the global community to address the threat of global warming.

Chroma actively promotes green product R&D and manufacturing with the goal of environmental sustainability, focusing on hazardous substance management, improving energy efficiency of power products, and increasing product recycling rates. To enable users to utilize testing equipment more efficiently while reducing energy consumption, technological innovation plays an important role in this process. Each year, Chroma develops a technology roadmap based on the Company’s business direction. Under the principle of not duplicating manpower on the same technology projects, R&D units coordinate to develop different innovative technologies or enhance the performance of existing technologies. In addition, the Advanced Technology Research Center focuses on researching core and advanced technologies to prepare for the technologies required for new products 2–5 years into the future. By maximizing manpower utilization, the aim is to increase the coverage of green equipment.

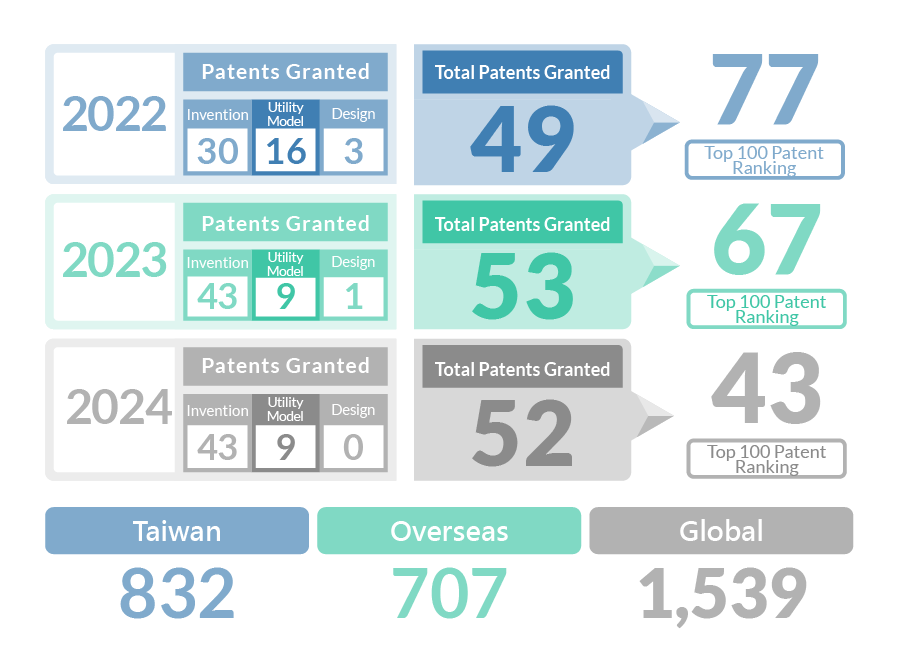

Innovative technologies & Patents

Within Chroma, an innovative culture and environment is actively fostered. Each year, the company rewards teams and individuals for their performance in technological innovation and product performance enhancement through the Innovation Technology Award and the Outstanding Engineer selection. In addition, the company also actively seeks external technological innovation, leveraging external resources to accelerate Chroma’s accumulation of technological capabilities. In 2024, Chroma collaborated with eight academic and research institutions/departments, including National Taiwan University, National Cheng Kung University, National Taiwan University of Science and Technology, and Wayne State University in the United States, with a total ongoing collaboration project value of NT$34.8 million. The company also engaged three technical consultants to provide technical guidance and consulting to R&D personnel.

Through the dedicated efforts of over 700 R&D personnel, innovative technologies have been transformed into patents. In 2024, Chroma filed 52 domestic and international patent applications, including 43 invention patents and 9 utility model patents. Patents were filed and granted in Taiwan, the United States, and China. The number of granted patents has increased year by year, demonstrating Chroma’s efforts in technological innovation and its emphasis on intellectual property rights.

Green Chroma Label

As a provider of measurement equipment, Chroma focuses not only on its own energy saving and carbon reduction efforts but also on helping users to effectively reduce carbon emissions when using Chroma instruments in their production processes. This is precisely the concept of the carbon handprint. Based on this concept, Chroma introduced the “Green Chroma Label” system to encourage all employees to plan, develop, and produce instruments that help users reduce carbon emissions.

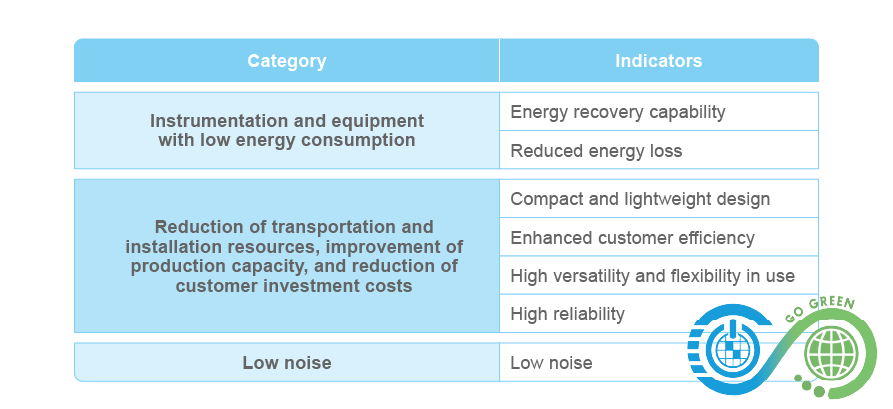

The Company assesses its products for the following characteristics throughout all stages of their lifecycle, including distribution and sales, product use, and waste disposal:

- Low energy consumption during use.

- Reduction of transportation and installation resources, improvement of production capacity, and reduction of customer investment costs.

- Design considerations for low noise to avoid harm to the physical and mental health of the user and finally to determine whether new products can bear the Green Chroma Label.

Products that have passed the audit will display the Green Chroma Label sticker on the back of the equipment to indicate their energy-saving effectiveness. Currently, applications for the Green Chroma Label are open to all Chroma product lines.

Product Life Cycle Assessment

Chroma adheres to the principle of continuous improvement and is committed to promoting the concept of sustainable product design. Based on the haracteristics of the product life cycle, comprehensive energy-saving and carbon-reduction management measures and new product design guidelines are established. Integrate environmental protection and resource efficiency strategies at every stage—from R&D, manufacturing, distribution, and use to recycling—to ensure that product design and development meet environmental sustainability requirements.

Product Design with Low Resource Usage

Including measures such as "reducing the number of components in the product or using shared modules," "using simulation or other effective tools to reduce the number of design revisions and shorten time, thereby reducing resource consumption," and "high-efficiency, high-quality testing and verification measures."

R&D personnel should make good use of innovative and digital technologies to reduce the number of product components, lower the carbon footprint, and improve resource efficiency. Additionally, during the new product or module development stage, priority should be given to the design and planning of shared modules. By using shared modules, energy and resource consumption during procurement and transportation can be effectively reduced, enhancing supply chain operations and shortening development cycles.

Moreover, during the R&D process, continuous improvement of computer-aided design (CAD) and engineering (CAE) technologies in the fields of electronics, mechanics, and optics should be pursued to verify design feasibility early, thereby reducing trial and error and avoiding resource waste. In terms of product verification, high-efficiency, energy-saving, and fully comprehensive testing technologies should be developed to reduce manpower input while ensuring verification efficiency and quality.

Component Use Control and Reduction

In raw materials, components, auxiliary materials, or packaging materials, environmental design concepts are introduced. According to Chroma's Control Standards for Hazardous Chemical Substances in Materials, the Company defines and manages its environmentally controlled substances, which are categorized into the following five types for control. R&D units must follow these measures when developing new products:

- RoHS restricted substances—hazardous chemical substances prohibited or restricted under the EU RoHS Directive and China’s Administrative Measures on the Control of Pollution Caused by Electronic Information Products.

- REACH SVHC restricted substances—substances of very high concern (SVHC) as announced by the European Chemical Agency (ECHA) that pose high risks to human health and the environment.

- Other regulated substances—hazardous chemical substances prohibited or restricted under the regulations of major trading countries, referenced against IEC 62474 material declaration standards for the electrical and electronic industry.

- Ozone-depleting substances (ODS)—controlled chemical substances announced under the Montreal Protocol.

- ELV and GADSL restricted substances—regulated substances defined in the EU End-of-Life Vehicles (ELV) Directive and the Global Automotive Declarable Substance List (GADSL).

In addition, suppliers are required to sign an Environmental Declaration and a Supplier Declaration of Non-Use of SVHC Substances and Non-Use of Conflict Minerals to ensure that products continue to comply with relevant regulatory requirements after mass production, moving Chroma's products toward sustainable management.

Reducing Overall Production Resource Consumption

Including measures such as "using better production processes" and "using improved testing, assembly, calibration, and burnin procedures."

To reduce overall resource consumption in production, production bottlenecks should be identified, advanced production processes introduced, and process efficiency improved. Testing, assembly, calibration, and burn-in procedures should also be optimized to make each stage of operation more efficient. Through these improvement measures, resource waste can be reduced and each process can achieve optimal operational status, helping to achieve a leaner production model while ensuring production stability.

Reducing Production Waste

Including measures such as "reducing waste in the production process" and "using fewer production fixtures."

To reduce production waste, the production process and design should be improved to lower the amount of waste generated during production while increasing material utilization. Additionally, by improving processes and standardizing design, reliance on production fixtures can be reduced, extending fixture lifespan or enabling multiple reuses, effectively minimizing unnecessary waste during production, reducing environmental impact, and improving overall production efficiency.

Lightweight and Compact Product Design

Product design should prioritize lightweight and compact form factors, reducing size and weight. Innovative technologies should be used to reduce the use of heavy components and increase channel density, enabling equipment to achieve the same capacity as traditional designs within a smaller volume. Lightweight and compact designs also increase transport load efficiency, reducing per-unit product energy consumption and improving logistics and transportation efficiency.

Transport-Friendly Packaging and Product Configuration

Packaging design should prioritize ease of transport, using lightweight, modular, and eco-friendly materials, reducing the use of filler, and improving space utilization. Product configurations should avoid unnecessary accessories or components, ensuring stability during transport and making handling easier. In addition, packaging should consider stackability and ease of combination to reduce transport losses and energy waste caused by improper packaging.

Using High-Efficiency Energy Management Technologies and Low Energy Loss Components

Including measures such as "developing equipment with energy recovery functions" and "reducing energy loss during equipment use."

High-efficiency energy management technologies can achieve precise energy distribution and control, avoiding unnecessary energy waste. At the same time, selecting low-loss components, such as high-efficiency power modules and low-impedance materials, can significantly reduce energy consumption during product operation and improve operational performance. Additionally, technologies with energy recovery functions should be actively implemented to recover energy that would otherwise be lost as waste heat during operation, achieving circular energy use and reducing energy consumption and carbon emissions.

Improving Capacity and Reducing Customer Investment Costs

Including measures such as "improving customer production efficiency," "products with high operational flexibility," and "products with long maintenance cycles and low maintenance difficulty."

Through technological innovation and design optimization, products should offer high accuracy and testing (inspection) speed, incorporate smart functions, and assist customers in process control through data analysis, helping customers achieve higher output and shorter delivery cycles. Furthermore, products should offer high operational flexibility, allowing quick adjustments and adaptations to different customer application scenarios or needs, improving equipment versatility and return on investment. This can be achieved by changing modules or developing multifunctional equipment. In addition, product design should focus on extending maintenance cycles to reduce the time and resources required for frequent maintenance, while also lowering maintenance difficulty, allowing customers to perform equipment maintenance with less specialized labor and lower costs.

User-Friendly Operation and Design for User Health

By designing user-friendly interfaces, operations can become more intuitive and easier to master. Integrated software control functions can effectively improve manual operation efficiency and reduce complexity during operation steps, lowering the risk of human error and enhancing overall operational reliability and accuracy.

Moreover, equipment design should pay attention to noise control during operation. By improving structural design, selecting low-noise components, and optimizing operating modes, noise levels should be continuously reduced to provide users with a quieter and more comfortable working environment. This helps prevent long-term noise exposure from affecting physical and mental health, thereby achieving a human-centric equipment design.

Selection of Sustainable, Recyclable, and Renewable Components and Packaging Materials

Priority should be given to selecting sustainable, recyclable, and renewable components and packaging materials to ensure that products can effectively reduce environmental impact at the waste stage, promote resource reuse, and lessen environmental burden.

Simplified Disassembly and Recycling Procedures

Product design should fully consider the ease of disassembly and separation of components. By adopting standardized and modular component designs, the disassembly process can be simplified, reducing dependence on specialized tools and manpower. In addition, material combinations should be optimized to avoid excessive use of difficult-to-separate composite materials, ensuring that each part can be quickly separated and sorted for processing.

For Chroma’s packaging materials and end-of-life equipment recycling, disposal is performed by the user. However, for PCBA, enclosures, standard accessories, and packaging materials, the content of toxic and hazardous substances or elements (including lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls/polybrominated diphenyl ethers, and phthalate compounds) in all homogeneous materials of these parts complies with SJ/T 11363-2006 and EU Directive 2011/65/EU and 2015/863/EU. The Company's product manuals provide detailed instructions on equipment disposal.

Green Design Results

From product line R&D to end-of-life product recycling, Chroma has already incorporated sustainable product design concepts. Below are examples from each stage of the product life cycle to demonstrate Chroma’s achievements in green sustainable product design.

A. Using simulations or other effective tools to reduce the number of design revisions and shorten time, thereby reducing resource consumption.

- Optical Simulation- Optical component point tester can be used for VCSEL optical characteristic LIV measurement. When evaluating a new customer’s product, it was found that the optical power attenuation measured at the OSA end was as high as 25 dB, which was much greater than the attenuation measured by the customer in their laboratory. After consulting with the customer to obtain the optical design values of the DUT, optical simulation revealed that differences in the new sample’s configuration and packaging tolerance caused the light spot size and position coupled into the optical fiber to deviate from the equipment’s optimal point. After appropriately increasing the packaging tolerance and adjusting the curvature of the focusing lens, a single optical design could now accommodate various DUT measurements.

- Mechanical/Thermal Simulation- The equipment uses a two-phase coolant transport copper tube for heat dissipation. During long-term operation, factors such as temperature differences, fluid pressure, or motor vibrations could cause the tube to crack and leak. The design first monitors vibration and pressure effects on existing tubing and finds that the copper tube’s strength is sufficient. However, repeated thermal expansion and contraction can cause fatigue failure. Literature suggests that adding bends to the tubing can absorb thermal deformation. Simulations were conducted with various bend designs and lengths to ensure the new tubing retains greater yield strength margin. After selecting the design, sample testing confirmed tubing reliability, saving time on multiple prototype and test iterations.

B. Reducing the number of components in the product, or using shared modules.

- The energy-regenerative AC power source and energy-regenerative AC electronic load were developed based on the same technology platform, with high component and module commonality, achieving a 100% commonality rate.

- Continued the digitalization of circuits policy to reduce component usage: Compared to the previous generation of power supplies, the new generation reduced the use of closed-loop control components by 50%.