Sustainable Supply Chain Management

Low-carbon supply chain

1. Test and measurement instruments

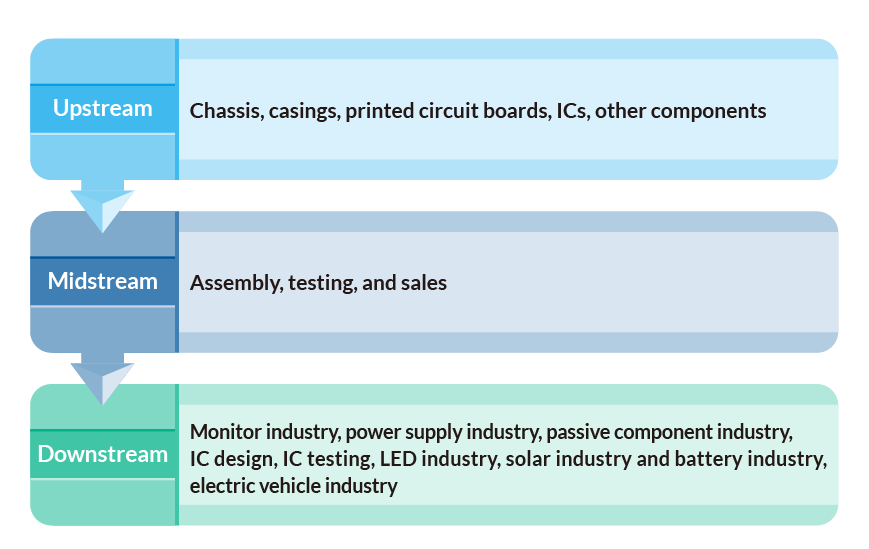

In the field of test instruments within the information electronics industry, products are mainly assembled by the Company and its subsidiaries using upstream components and then marketed to customers under the Company's own brand. The Company and its subsidiaries offer an extensive selection of solutions for product testing and validation purposes to customers from many fields such as video surveillance, passive components., LCD modules, LED, semiconductor, photovoltaics (PV), and electric vehicle industries. An illustration of the upstream, midstream, and downstream industry linkages is as follows:

In the area of automatic equipment, the Company combines measurement equipment, automation systems, and MES software capabilities to provide customers with integrated automation solutions (Turnkey Solution). The Company's subsidiary, MAS AUTOMATION CORP., mainly provides diverse integrated solutions, including solar module line automation production and system integration, TFT-LCD automation production and system integration, battery module automatic testing systems, and cleanroom equipment planning and system integration.

The instruments produced by Chroma and its subsidiaries are characterized by low volume and high variety, requiring a wide range of raw materials. The main raw materials include FPGA ICs, power converter ICs, memory, relays, mechanical components, and circuit boards. Currently, these are all sourced through more than three suppliers who distribute products from globally renowned manufacturers. These suppliers have long-term cooperative relationships with the Company, with stable quality and supply, and maintain good relations with Chroma. To ensure interchangeability and competitiveness between suppliers, thereby diversifying procurement risks and appropriately reducing costs while obtaining better services, procurement is centrally managed by the procurement department through both domestic and international vendors. The purchasing unit shall regularly review quotations offered by the supplier. QC and purchasing personnel shall conduct audits at the supplier end to ensure the stability of product quality while assessing the production capability of the supplier.

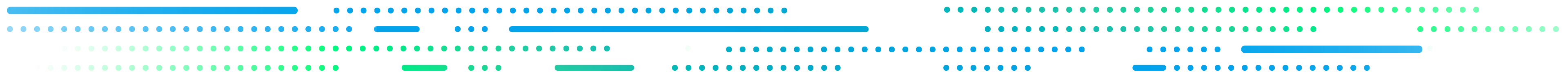

Local procurement

The proportion of local procurement in Taiwan remains above 89%

Partnering with Suppliers for Green Transformation

Description

1. Return cartons to suppliers for reuse.

2. Recycle and reuse wooden crates and pallets.

2024 Performance

A total of 17 metric tons of cardboard boxes and 3,997 wooden pallets were recycled and reused within the plant, and returned to suppliers for“ reuse,” achieving an 80% packaging material recycling rate.

2025 Performance

1. Target of recycling 20 tons of cartons.

2. In-house recycling and reuse target of 4,500 wooden crates and pallets.

3. The three main carton suppliers have completed FSC certification and are expected to fully implement this in 2025.

Key Components and Hazardous Chemicals Control

- RoHS-limited substances: in compliance with the EU RoHS Directive and China’s "Administrative Measures on the Control of Pollution from Electronic Information Products," prohibiting or restricting the use of hazardous chemical substances.

- REACH-SVHC-limited substances: as announced by the European Chemical Agency (ECHA), substances of very high concern (SVHC) that are highly hazardous to humans and the environment.

- Other regulatory limited substances: under relevant regulations, as stipulated by the main trading countries' laws prohibiting

or restricting hazardous substances, with reference to IEC 62474 Material Declaration Standard for the electrical and

electronic industry.

- Ozone Depleting Substances (ODS): controlled chemical substances announced under the Montreal Protocol.

- ELV- and GADSL-limited substances: as defined in the EU End-of-Life Vehicles Directive and the Global Automotive Declarable Substance List (GADSL). In addition, suppliers are required to sign an Environmental Declaration and a Supplier Declaration of Non-Use of SVHC Substances and Non-Use of Conflict Minerals to ensure that products continue to comply with relevant regulatory requirements after mass production, moving Chroma's products toward sustainable management.

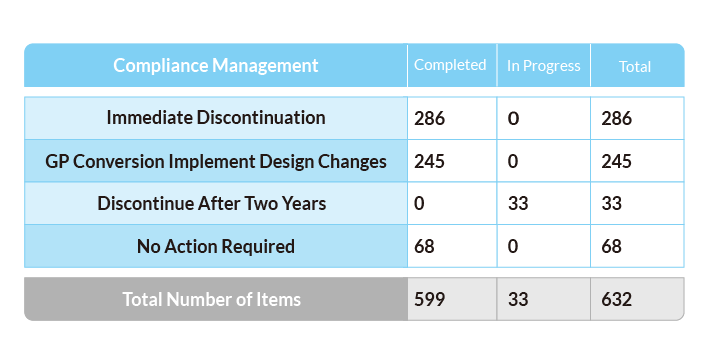

Since Chroma began implementing hazardous chemical substance control in 2005, all new products have met environmental requirements, and most older products have also been converted to meet compliance. As of the beginning of 2023, there were still 632 products not yet compliant. After product discontinuation and design changes, all were in compliance with control requirements by the end of 2024.

Supplier management

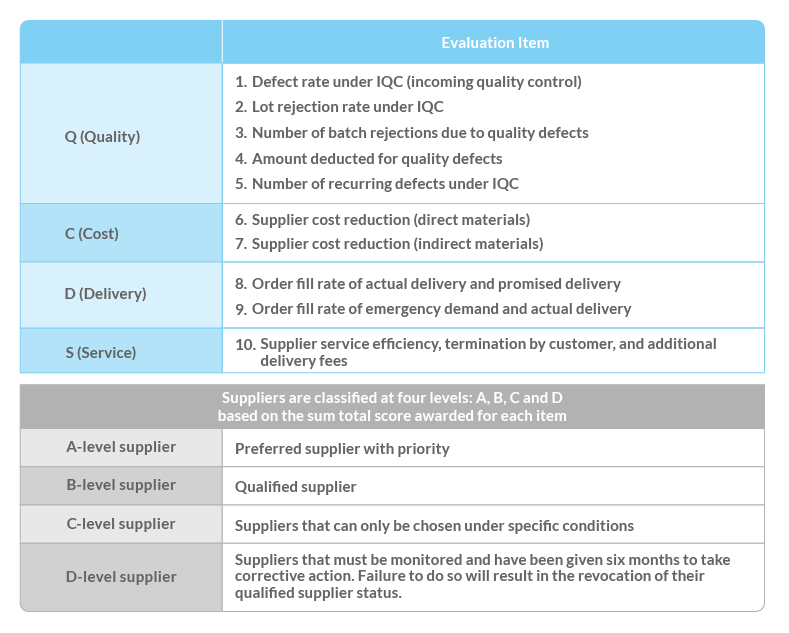

In accordance with the “Supplier Management Procedures,” when selecting new suppliers, the procurement unit requests suppliers to provide material pricing, lead time, specifications, or samples, which are then reviewed and confirmed by the relevant requesting units. Suppliers are also required to perform a self-assessment, and on-site evaluations are conducted when necessary.

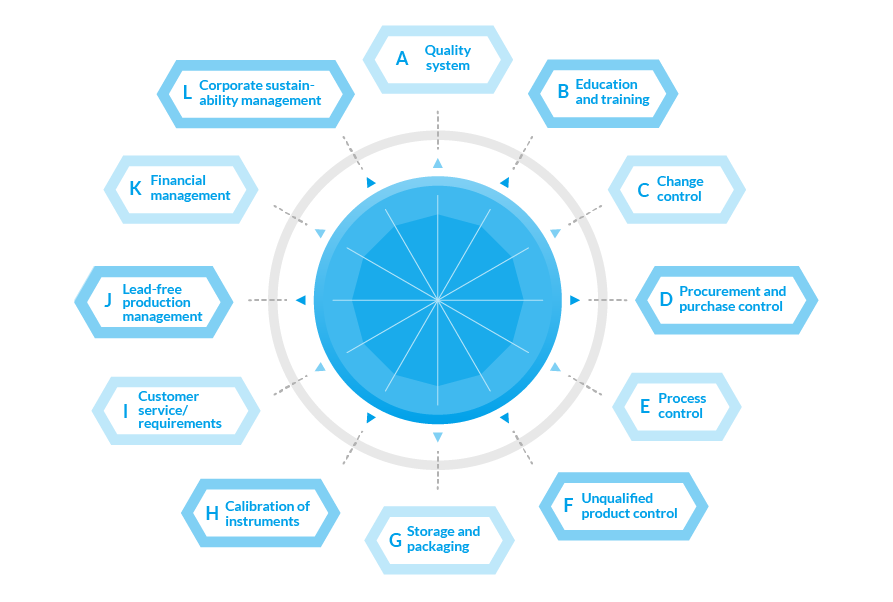

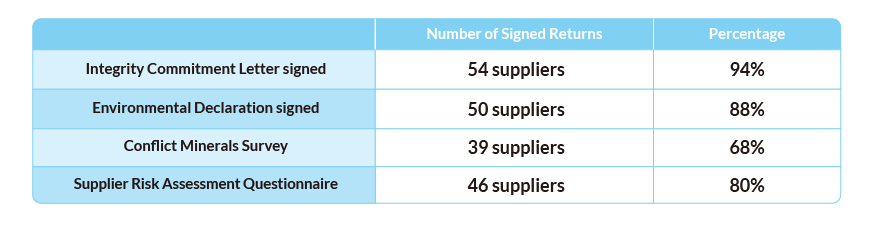

The evaluation items include A–M, a total of 12 items. Among them, the corporate sustainability management section includes environmental management, occupational health and safety management, corporate social responsibility, and hazardous substances management. In 2024, there were 54 new suppliers, all of whom underwent corporate sustainability management evaluation.

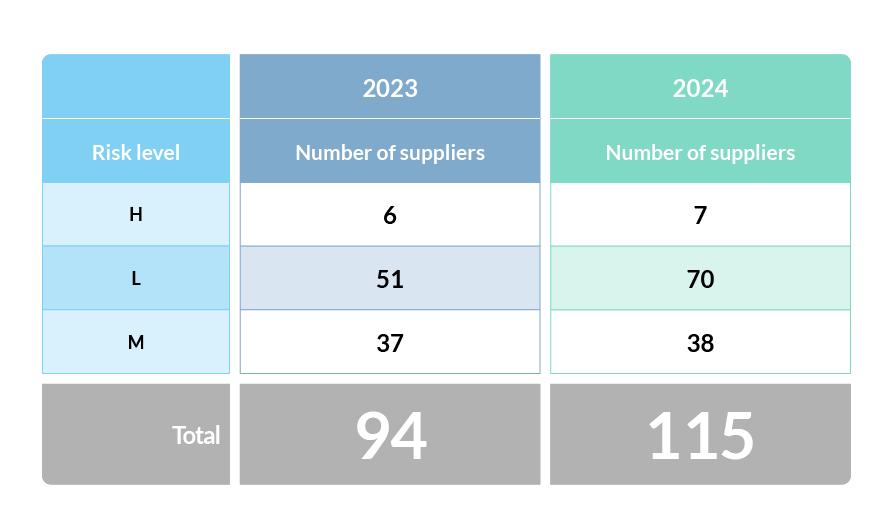

Supplier Risk Assessment Questionnaire (New and Existing Suppliers)

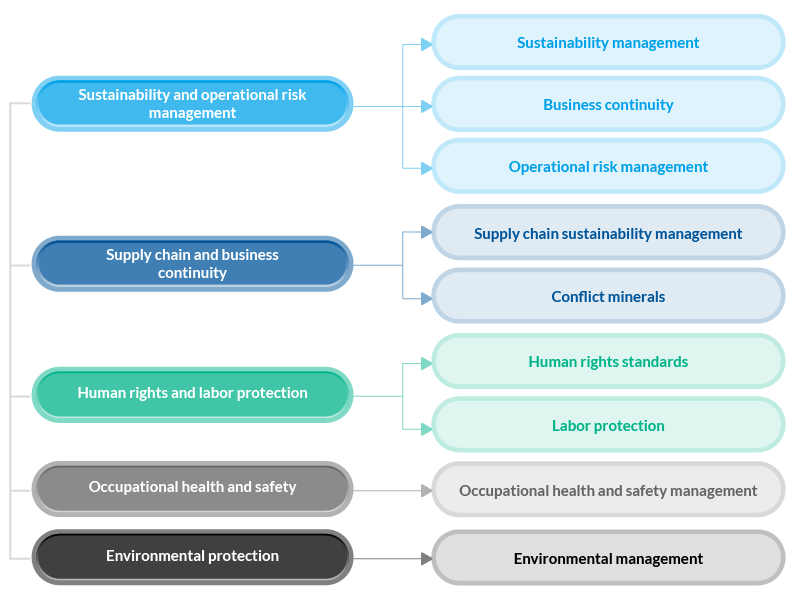

In addition, to further understand how new suppliers are preparing for the current wave of ESG initiatives, a risk assessment questionnaire is conducted alongside the supplier self-assessment. The assessment covers:

Key Suppliers

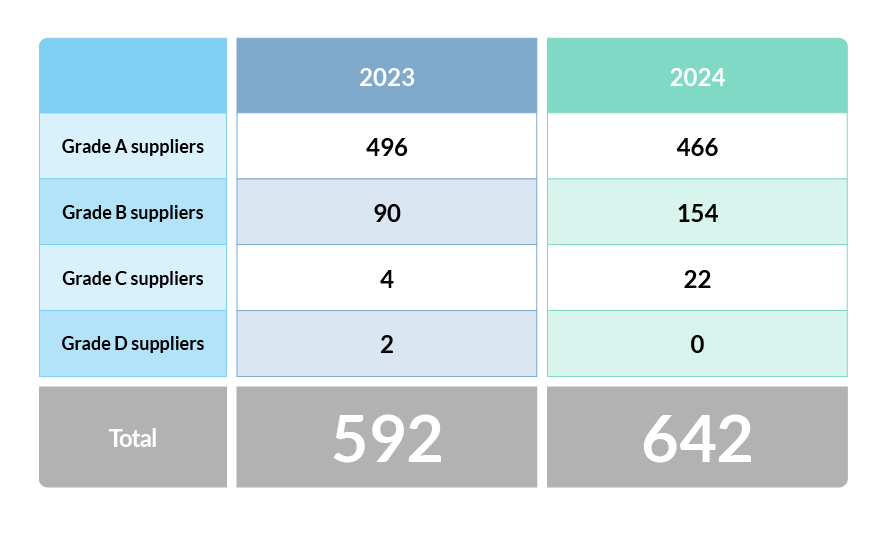

To build a sustainable supply chain, we classify key suppliers based on annual transaction amounts.

- Tier-1 Suppliers: 642

- Significanr Tier-1 Suppliers: 149

According to the "Environmental Consideration Identification and Risk Assessment Operation Guidelines," suppliers whose life cycle impact level is determined as "Influential" are identified, and their environmental management and environmental protection performance are confirmed. Suppliers with M/H risk levels or transaction amounts above NT$5 million are subject to evaluation.