Sustainable supply chain management

We have formed most important strategic partnerships with our customers. In addition to offering them valued products and services, we also concern ourselves with social and environmental values. We are a world class enterprise that has a corporate mission "to develop globally leading products for a sustainable supply chain". We collaborate with the supply chain and share social and environmental responsibilities with them.

In addition, we require that the supply chain understands and appreciates our sustainable operations and supplier code of conduct. We tolerate no compromises, corruption, or bribery activities. Chroma is committed to the implementation of environmental protection and care for the workplace environment and the safety of our employees. We make every effort to reduce environmental impact and protect the health and welfare of our employees. We also require our suppliers to care for their workplace environment, the safety of the supply chain workers and ensure that they are treated with respect and dignity. We expect business operations to be environmentally responsible and conducted ethically. Compliance to these requirements by a supplier is one of the major considerations of a procurement decision.

As climate change worsens, specific economies are committing to challenging greenhouse gas reduction targets to achieve global net-zero sustainability. While Chroma has promised to reduce the carbon footprint of its own products and services, it now also expects its international trading partners and suppliers to pursue the same sustainable goal. Manufacturing has always focused on the improvement of production capacity and yield. Now net-zero manufacturing has been added as a target and in addition to fast and good production, more emphasis is being placed on clean production.

As climate change worsens, specific economies are committing to challenging greenhouse gas reduction targets to achieve global net-zero sustainability. While Chroma has promised to reduce the carbon footprint of its own products and services, it now also expects its international trading partners and suppliers to pursue the same sustainable goal. Manufacturing has always focused on the improvement of production capacity and yield. Now net-zero manufacturing has been added as a target and in addition to fast and good production, more emphasis is being placed on clean production.

Key components and control of hazardous chemical substances

By implementing eco-design with respect to materials, parts, accessories, and packaging, and based on our “Standards for Controlling Hazardous Chemical Substances in Materials”, we have categorized environmentally controlled substances into the following five groups:

- RoHS-limited substances: All hazardous chemical substances restricted or limited by the EU Restriction of Hazardous Substances (RoHS) and Chinese Measures for the Control of Pollution from Electronic Information Products.

- REACH-SVHC-limited substances: Substances of Very High Concern (SVHC) to humans and the environment published by the European Chemical Agency (ECHA).

- Other regulatory limited substances: Hazardous chemical substances whose use is restricted or limited by law in the major trading countries. Please refer to IEC 62474 - Material Declaration for Products of and for the Electrotechnical Industry.

- Ozone Depleting Substances (ODS): Please refer to the controlled chemical substances published in the Montreal Protocol.

- ELV- and GADSL-limited substances: Controlled substances defined in the Directive 2000/53/EU on End-of-Life Vehicles (ELV) and Global Automotive Declarable Substance List (GADSL). We also require suppliers to sign a “Statement of Environmental Protection” and the “Statement of SVHC Substance-Free and Conflict Metal-Free” to ensure continuous legal compliance of mass-produced products and to ensure Chroma maintains production sustainability. We have introduced the concept of green product design in the R&D process. This division is tasked with making products more energy-efficient and ensure their compliance with all the regulations on hazardous chemicals. We use renewable and recyclable materials as many as possible. Improvement and evaluation are carried out on a continuous basis to ensure that our mass-produced products meet the requirements and standards of quality assurance and environmental protection.

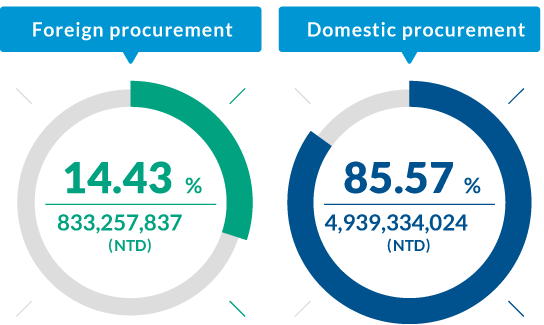

We maintain a highly-efficient and versatile supply chain in Taiwan with local procurement of more than 85%.

We maintain a highly-efficient and versatile supply chain in Taiwan with local procurement of more than 85%.

Our strategic partnerships with suppliers are not only important because they allow us to offer our customers valued products and services, but because they include great social and environmental value. We have a vital corporate mission “to develop globally leading products as a world-class enterprise” using a sustainable supply

chain. We share this social and environmental responsibility with the supply chain.

Chroma and its subsidiaries produce a diverse assortment of instruments in small quantities. A wide range of raw materials are required which include main materials such as programmable gate array ICs, converter ICs, memory chips, relays, materials for making enclosures, PC boards and so on. Currently, we have three or more

suppliers for each type of material who are our long-term partners. We have excellent relationships with our suppliers who are all distributors for the products of world-famous manufacturers, and their quality and supply of materials are stable. At present, materials are collectively purchased from domestic and foreign manufacturers by

our procurement unit. If possible two or more competitive suppliers are selected for each component which must always be interchangeable. This diversification minimizes procurement risk, keeps the prices down, and allows us to enjoy better services. The procurement unit regularly reviews the prices and the suppliers are audited by our quality control and procurement personnel to ensure both quality and stability and to monitor their manufacturing capacity and supply.

There were no significant changes in the main supplier data or their consolidated financial statements in 2022. (Suppliers of more than 10% of net purchases in the last two years). As there were 91 new suppliers, onsite evaluation is conducted on 13 suppliers each year.

Suppliers are key partners in our Company operations and share our common pursuit of sustainable management and growth. We adhere closely to a policy of local procurement to maintain a highly efficient and versatile supply chain. Chroma maintains a local Taiwan procurement rate of more than 85%. ('local' means 'in Taiwan').

chain. We share this social and environmental responsibility with the supply chain.

Chroma and its subsidiaries produce a diverse assortment of instruments in small quantities. A wide range of raw materials are required which include main materials such as programmable gate array ICs, converter ICs, memory chips, relays, materials for making enclosures, PC boards and so on. Currently, we have three or more

suppliers for each type of material who are our long-term partners. We have excellent relationships with our suppliers who are all distributors for the products of world-famous manufacturers, and their quality and supply of materials are stable. At present, materials are collectively purchased from domestic and foreign manufacturers by

our procurement unit. If possible two or more competitive suppliers are selected for each component which must always be interchangeable. This diversification minimizes procurement risk, keeps the prices down, and allows us to enjoy better services. The procurement unit regularly reviews the prices and the suppliers are audited by our quality control and procurement personnel to ensure both quality and stability and to monitor their manufacturing capacity and supply.

There were no significant changes in the main supplier data or their consolidated financial statements in 2022. (Suppliers of more than 10% of net purchases in the last two years). As there were 91 new suppliers, onsite evaluation is conducted on 13 suppliers each year.

Suppliers are key partners in our Company operations and share our common pursuit of sustainable management and growth. We adhere closely to a policy of local procurement to maintain a highly efficient and versatile supply chain. Chroma maintains a local Taiwan procurement rate of more than 85%. ('local' means 'in Taiwan').

Selection and recognition of new suppliers

The selection of a new supplier is done in accordance with the "Supplier Management Procedure". The procurement unit requests price, delivery time, specifications or samples of the material from the supplier and submits the information to the relevant units for confirmation. The supplier is also required to make a selfevaluation.

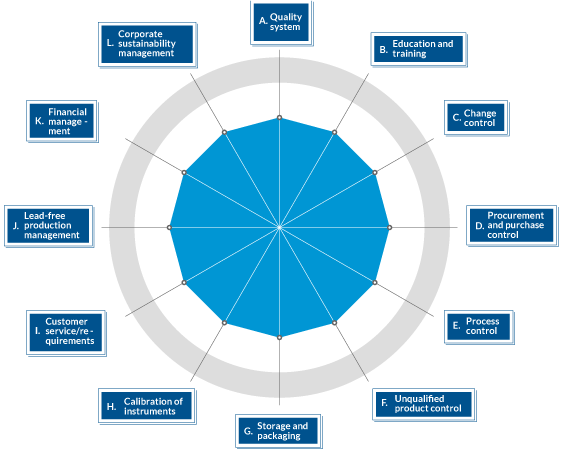

In addition to ISO 9001/IATF 16949 certification and compliance with SONY Environment-related Substances to be Controlled requirements, we also encourage new suppliers of direct materials to have ISO 14001 certification. Furthermore, they must also pass an physical inspection audit of procurement, quality, technology,

and hazardous substances before they are eligible to become qualified Chroma suppliers (vendors). A total of 12 evaluation items are listed as A to M below. This must include corporate sustainable management, such as CSR and hazardous substances management; environmental management including energy and GHG emission; occupational safety and health management including labor health and workplace safety. Furthermore, suppliers determined to have "likely" impact on the life cycle as specified in the "Regulations for Identification of Environmental Aspects and Risk Assessment" are requested to complete and sign a "New Suppliers Environmental Management Survey Form" to validate their achievements in environmental management and environmental protection.

Suppliers of Medium / High risk levels and those engaging in transactions exceeding a value of NTD 5 million have to be evaluated. In 2022, 96 suppliers were evaluated, and the results showed that 3 were considered to be high-risk (H), the others fell into the medium (M; 22 suppliers) to low (L; 71 suppliers) risk range. We referred the

high-risk suppliers to the environment and safety unit and a survey was conducted using the Environmental, Health, and Safety Checklist to determine the need for physical inspection audit. After re-evaluation, the environment and safety unit lowered the risk level of the three high-risk suppliers to medium-risk.

Note: H-level means having been sanctioned by the competent authorities in the past three years; M-level means being control-listed by the environmental protection unit.

In addition to ISO 9001/IATF 16949 certification and compliance with SONY Environment-related Substances to be Controlled requirements, we also encourage new suppliers of direct materials to have ISO 14001 certification. Furthermore, they must also pass an physical inspection audit of procurement, quality, technology,

and hazardous substances before they are eligible to become qualified Chroma suppliers (vendors). A total of 12 evaluation items are listed as A to M below. This must include corporate sustainable management, such as CSR and hazardous substances management; environmental management including energy and GHG emission; occupational safety and health management including labor health and workplace safety. Furthermore, suppliers determined to have "likely" impact on the life cycle as specified in the "Regulations for Identification of Environmental Aspects and Risk Assessment" are requested to complete and sign a "New Suppliers Environmental Management Survey Form" to validate their achievements in environmental management and environmental protection.

Suppliers of Medium / High risk levels and those engaging in transactions exceeding a value of NTD 5 million have to be evaluated. In 2022, 96 suppliers were evaluated, and the results showed that 3 were considered to be high-risk (H), the others fell into the medium (M; 22 suppliers) to low (L; 71 suppliers) risk range. We referred the

high-risk suppliers to the environment and safety unit and a survey was conducted using the Environmental, Health, and Safety Checklist to determine the need for physical inspection audit. After re-evaluation, the environment and safety unit lowered the risk level of the three high-risk suppliers to medium-risk.

Note: H-level means having been sanctioned by the competent authorities in the past three years; M-level means being control-listed by the environmental protection unit.

Chroma welcomes your voice, please don't hesitate to contact us!